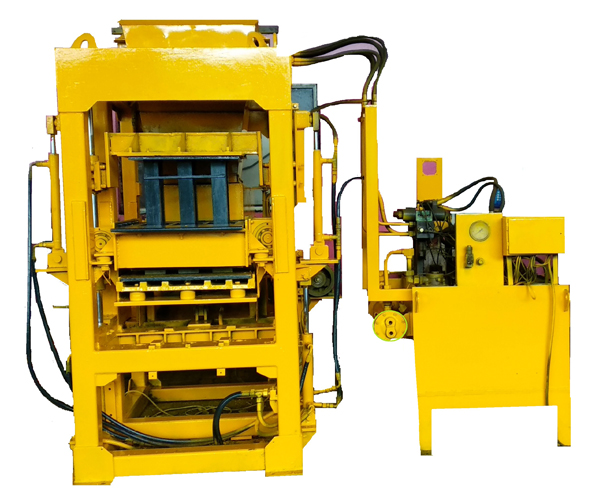

Product Name |

Cavity |

Cycles / minutes |

Production Capacity |

| Fly ash bricks 9 x 4 x 3 | 6 | 6 | 19200 bricks / shift |

| Color Pavers | 6 | 6 | 15000 pavers / shift |

| Uni Pavers | 6 | 6 | 19200 uni pavers / shift |

| Concrete Blocks | 3 | 5 | 7200 Blocks / shift |

| Energy Transmission | Vibro Hydraulic compaction |

| Energy source | Electrical, 3 phase, 440 volts |

| Electronics control | PLC base fully automatic |

| Motor | 15 Hp SIMENS make |

| Hydraulic pressure | 25 Ton |

| Vibrator | 05 + 05 HP (mold vibration ) |

| Hydraulic oil tank | 400 Liters |

| Cycle time | 10 seconds |

| Stroke per minute | 06 stroke |

| Cooling | Condenser type cooling |

| Total power required | 35.00 Kw / 46 Hp |

| Pallet size | 650 x 550 x 06 mm (Mild steel) |

| Number of pallets | 1200 pallets |

| Total labour required | 02 Skilled + 04 Unskilled labours |

Vibration Technology

This machine has direct mold vibration technology, which gives you the best synchronized vibration PLC control with hydraulics and electrical, Mold vibration technology is best ever than pallet vibration.

Multi Product Machine

This machine manufacture concrete blocks, bricks, uni pavers, colour layer pavers with vibro compaction technology.(this product is commonly used for government project).

Material Feeder

Individual material feed box is provided for both back layer and top layer

Mold Life

Material for mold is HCHCR D2 having 55 HRC hardness gives 4,00,000 cycles mold of life

Pallet feeding and collecting system

This machine has an automatic pallet feeding and ejection system controlled by PLC. Pallet stacking machines are also supplied in this plant.

Electricity Consumption

High quality electronics components, motors, vibrators and high efficiency gearboxes will consumes less power for production

Minimum labour required

Fully auto and manual controls are designed to operate by semi skilled workers. Only 02 skilled and 04 unskilled labours required in fully automize plant.